Lantana briquetting; Invasive weed control to sustainable energy

Lantana camara is an invasive weed that is taking over numerous forests in India. The forest department has been trying to eradicate the plant for over a hundred years now in south India, but with no success, as the plant continues to spread. At TST, we’ve been trying to find uses for the plant and to get local people to cut and extract the plant in the hope that this will control the plant in the forests, while also help local communities. Lantana furniture was the first initiative, and we are now looking to convert Lantana into briquettes to use as a fuel source.

Here is an outline of the briquetting process that we hope will be useful for other communities/NGOs looking to do similar things.

The briquetting industry is flourishing in India. Agricultural activities create a number of waste products like dried leaves, branches/stalks, small twigs etc. Generally all this cut waste is directly burnt which is wasteful and also harmful to the environment. Biomass briquettes are an environment friendly, efficient solution to recycling agriculture and forest waste while simultaneously creating clean fuel for burning purposes. These days a number of industries are using bio-mass briquettes for generating heat in their boilers. These compact and easy to use bio-mass briquettes can also be used at the household level for cooking fuel as an alternative for firewood. And when we consider the ordeal many tribal communities face in gathering increasingly scarce firewood from distant places, briquettes seem to be an easier alternative and a solution with significant social impact. Rural areas which are generally blessed with rich natural resources can look at bio-mass briquetting as an option with good potential to generate livelihood especially since the technology is fairly simple. Any bio-mass has to be dried to bring it to a suitable moisture content (10-15%) and then ground to suitable size. The dust is filtered out and then a pressing machine is used to apply pressure on the powdered bio-mass to compact it into briquettes. The pressure when applied releases lignin from within the bio-mass which binds the material together. In certain bio-mass materials an artificial binder has to be used to compact it together.

RAW BIOMASS -> DRYING -> GRINDING TO SUITABLE SIZE -> FILTERING THE DUST -> PRESSING/COMPACTION->BRIQUETTE

Some pointers to keep in mind while planning for a bio-mass briquetting project

- It is important to map the bio-mass which is to be used as a raw material and ensure that a sizeable quantity is available. Adequate availability of raw material is the single most important factor to be considered while planning for a briquetting project.

- Bio-mass briquetting is a thin margin industry and it is important to ensure that the customers are present close to the production centers. Logistics forms an important part of the costs and it is important to ensure that the raw material source, production unit and the customers are as close as possible to eliminate unnecessary logistics costs.

- There are technology options available ranging from processing a few kilos of bio-mass in a day to large scale industrialized production systems which process hundreds of tons. The technology option to be selected should be based on the project requirements. Especially while determining the scale; it would be important to consider one’s bandwidth for collection and loading of bio-mass. It is important to ensure that there is an option to fix maintenance issues in the machines in a timely manner.

- To ensure good quality briquettes the size (10 mm) and moisture content of the raw material (10-15%) being input in the pressing machine should be kept within limits. Otherwise it would result in loosening or breakage of the briquette.

- In general the costs can be broken down to Raw material extraction and loading cost (per kg) + transportation of material to briquetting unit/machine (per kg) + Processing cost( (including drying) per kg of material) + Packaging, marketing and delivery costs (per kg). The addition of the above costs would give your per kg cost of the briquette.

- It might be useful to consider the rainfall patterns in the region as it would have an impact on the moisture content in the raw material and hence affect the drying process Also check the power availability/outages in the region if one is going for an electrical production system as any downtime would affect the viability of the project.

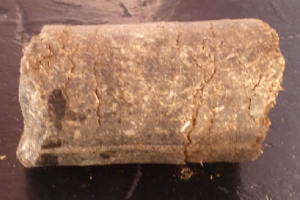

- Market acceptability of the product and customer satisfaction is the key to the success of any commercial project. Even though briquetting seems to be a good opportunity, before investing money it is advisable to locate the customers, understand their requirements and probably let them test some briquettes for constructive feedback. (This blog is just to give one a broad overview of bio-mass briquetting and is not exhaustive by any standards. The briquetting technology set up at Tamil nadu agricultural university, Coimbatore may be a good starting point to understand briquetting. Please find below a few snapshots of what a briquette looks like.)